ORNL’s advanced manufacturing expertise has drawn numerous partners in Ohio, including Reuter-Stokes, a producer of measurement equipment; Strangpresse, an additive manufacturing extruder developer; Cincinnati Incorporated, a machine tools innovator; and Melink, a full-service solar power firm.

ORNL’s user facilities offer a diverse set of tools for experiments across a range of fields, including biology, materials and energy sciences, physics, engineering, and chemistry. Learn more about ORNL’s user facilities. Data reflects fiscal year 2020 except for scientific publications, which covers 2016–2020. Partner stories reflect work conducted from 2016 to present.

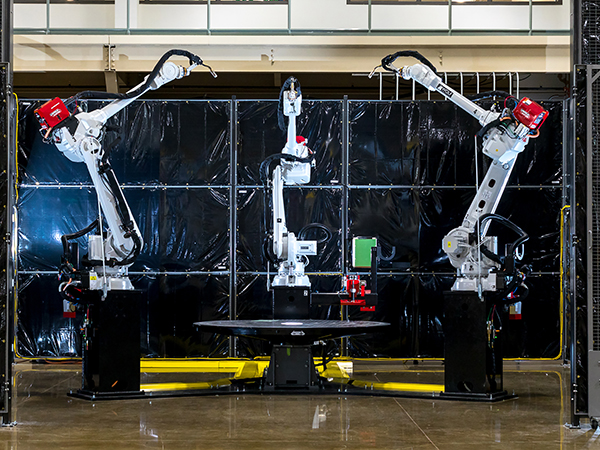

ORNL partnered with Lincoln Electric, based in Cleveland, and Wolf Robotics, based in Fort Collins, Colorado, to accelerate technology for additive manufacturing, significantly reducing the time and cost it takes to make large metal parts for automotive, aerospace, and energy industries. Through the development of improved materials and controls, this partnership has opened doors for localized manufacturing by forging new ground for rapidly printing large-scale metal parts. In 2017, ORNL demonstrated the impact of this system by fabricating the arm of a mini excavator in about five days, illustrating how additive manufacturing can be used to create single components with complex geometries.

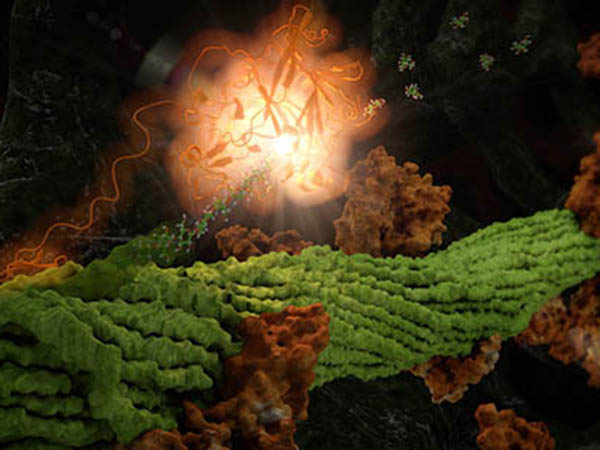

In Ohio, researchers at the University of Cincinnati are collaborating with ORNL scientists to better understand the conversion of plant biomass into valuable products at a molecular level, with discoveries aimed at improving the production of abundant domestic biofuels, chemicals, and materials. The research is supported by the DOE Solvent Disruption of Biomass and Biomembranes Science Focus Area led by ORNL. Projects leverage ORNL capabilities such as neutron scattering, computing, and biological expertise to provide fundamental insights into how solvents alter the structure and arrangement of plant cell walls and microbial membranes.

Learn more about biological science at ORNL.

ORNL and the University of Toledo partnered to develop high-strength, intelligent, lightweight materials for the automotive industry, enhancing vehicle performance and efficiency. ORNL’s expertise in manufacturing, carbon fiber composites, machining, energy storage, and metrology complemented the university’s strengths in manufacturing system modeling, metals engineering, and assembly systems. This collaboration also engaged Ohio’s automotive industry, driving innovation and commercialization in a key manufacturing hub.

Learn more about energy research at ORNL.

ORNL news release: “ORNL, University of Toledo to Collaborate on Advanced Materials, Manufacturing Research for Vehicle Applications”

The COMPASS–Great Lakes Modeling project brings together ORNL with other national laboratories and university partners to analyze data on the effects of agricultural watersheds on Ohio’s western Great Lakes region. Scientists are working to improve estimates of nutrient runoff that causes harmful algal blooms in the Great Lakes, threatening regional freshwater resources. Partners are The University of Toledo, Baylor University, Michigan Technological University, Heidelberg University, Argonne National Laboratory, and Lawrence Berkeley National Laboratory.

For more information, contact [email protected].