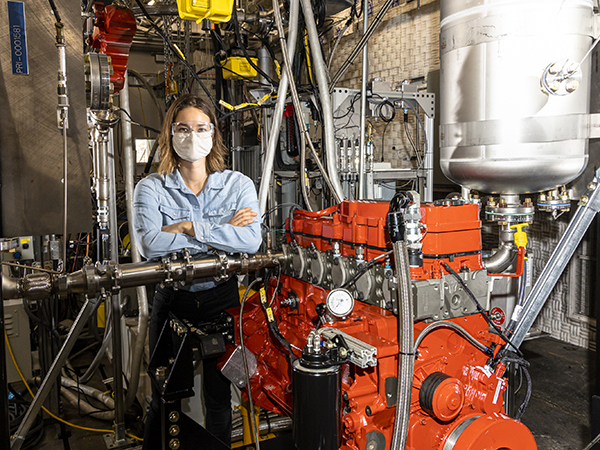

Advanced manufacturing and biomedical science are cornerstones of industry in Indiana. ORNL has worked across Indiana’s industrial gamut—from its largest high-impact companies down to its small startups that are opening new doors for science. ORNL has a long history with Cummins, a Hoosier State giant focused on diesel and alternative–fueled engines, diesel and alternative-fueled electrical generator sets, and related components and technology. This solid partnership yielded creative problem-solving during the COVID-19 pandemic, putting millions of high-quality masks in the hands of healthcare workers.

ORNL’s user facilities offer a diverse set of tools for experiments across a range of fields, including biology, materials and energy sciences, physics, engineering, and chemistry. Learn more about ORNL’s user facilities. Data reflects fiscal year 2020 except for scientific publications, which covers 2016–2020. Partner stories reflect work conducted from 2016 to present.

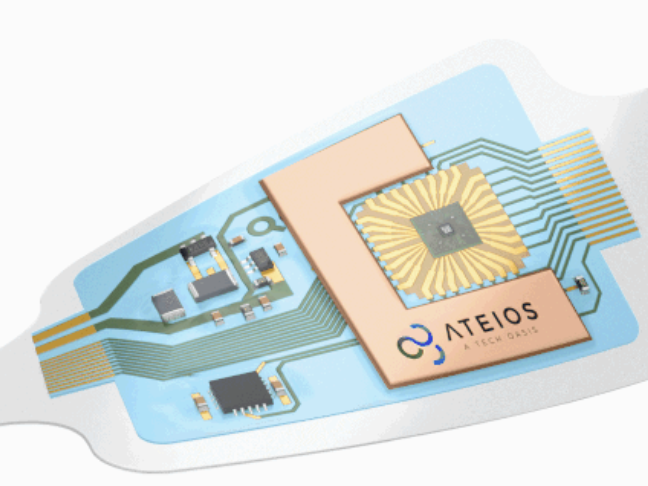

Ateios Systems, a startup that is reshaping battery manufacturing, has licensed an ORNL technology that will enable the company to produce batteries that are more efficient and more cost effective. The company’s near-term focus is to manufacture ultra-thin batteries for wearable devices and other objects embedded with sensors or processing systems. This promising design will help clear the way for the widespread use of lightweight, flexible batteries in products like continuous glucose monitors, sleep trackers, and other related devices. The transfer of technology between the two institutions was recognized by the Federal Laboratory Consortium for Excellence in Technology Transfer. Learn more about energy research and physical science at ORNL.

Learn more about energy research and physical science at ORNL.

Through its partnership spanning more than 30 years, ORNL has licensed technologies to and has held multiple R&D agreements with Cummins across all aspects of engine technology, advanced materials, and manufacturing. As a leading manufacturer of filtration products for use in heavy-duty diesel engines, Cummins has created a way to use their filtration production technology to support healthcare providers during the COVID-19 pandemic. Cummins teamed with ORNL’s Carbon Fiber Technology Facility to create a process for producing the fabric used in respirators to reduce the spread of viruses, such as COVID-19. As a result of collaboration, Cummins produced enough filter media to supply more than a million face masks and respirators per day.

Through a partnership with the Naval Surface Warfare Center in Crane, ORNL is developing materials and processes to enable rapid, low-cost production of radomes, large dome-shaped structures used to protect radars from the elements. This project integrates additively manufactured autoclave tooling with direct printing for core structures on curved surfaces.

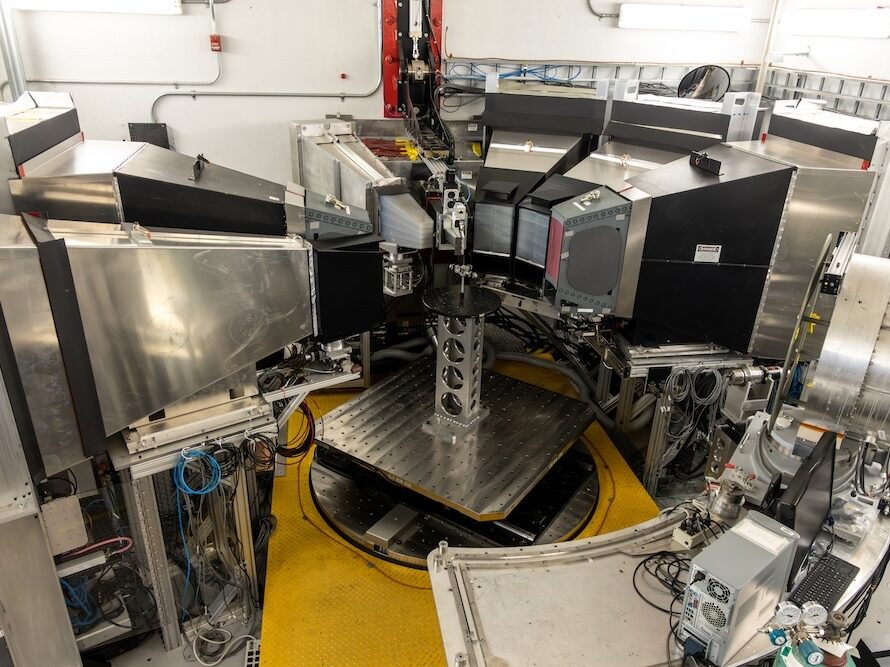

ORNL is partnering with Purdue University, located in West Lafayette, Indiana, to develop new algorithms that reduce scan time and improve the quality of computerized tomography (CT) images for different applications. One area of collaboration is neutron CT, a critical tool at scientific user facilities around the world, including the Spallation Neutron Source at ORNL. At these facilities, researchers apply for limited time available to study materials, leading to scientific breakthroughs in fields such as biology, physics, and engineering and to a greater understanding of matter. Using AI- and model-based algorithms, ORNL and Purdue researchers are delivering significant image improvement at three to five times the current scanning speeds. In a separate collaborative project using an AI-driven approach, researchers are using 3D models of additively manufactured parts to reduce the number of x-ray CT scans needed to more rapidly assure the quality of 3D printed parts.

For more information, contact [email protected].