ORNL and Massachusetts academic institutions and technology firms are working together to tackle the world’s biggest science and energy challenges. ORNL technology has been licensed for commercial use to the following companies: Memcus, specializing in next-generation memory chipsets; 908 Devices, bringing innovation to handheld and desktop instruments for analytical laboratories; and Enchi Corporation, leveraging expertise to provide economically feasible biofuels.

ORNL also has research agreements with Commonwealth Fusion Systems, leveraging decades of fusion research combined with innovation from the private sector; Radiation Monitoring Devices, providing radiation detection, high-speed imaging, nuclear instrumentation, and laboratory test equipment; and Kalion, making high-quality chemicals from biomass.

ORNL’s user facilities offer a diverse set of tools for experiments across a range of fields, including biology, materials and energy sciences, physics, engineering, and chemistry. Learn more about ORNL’s user facilities. Data reflects fiscal year 2020 except for scientific publications, which covers 2016–2020. Partner stories reflect work conducted from 2016 to present.

ORNL buildings and materials science researchers worked with Flexcon Global to develop a resilient, self-healing barrier film for insulation panels and an advanced method for manufacturing the film using a cost-effective roll-to-roll coating process. The film was produced using the resources of the Building Technologies Research and Integration Center, where scientists investigated material chemistries to improve the robustness of the insulation panels to prevent costly damage. The film and the related manufacturing process can be used for a wide range of products and applications, including storage, packaging, food, and pharmaceuticals.

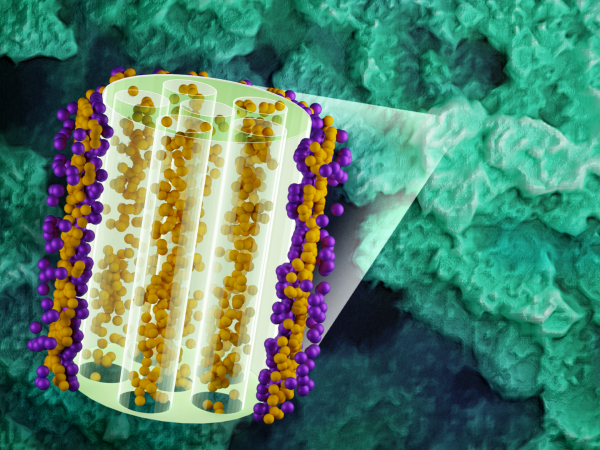

Unlike batteries, capacitors release energy quickly for applications that require faster power. Newer capacitors, called supercapacitors, are made from advanced materials that offer higher energy storage and increased power with a virtually unlimited cycle life. However, even higher energy densities will be needed to enable supercapacitors to one day serve as sole power sources in high-power applications such as electric vehicles. Scientists from the Massachusetts Institute of Technology conducted neutron research at the ORNL’s High Flux Isotope Reactor to investigate a new, highly porous nanomaterial that could function as durable, high-energy supercapacitors. Learn more about neutron science at ORNL.

Molten salt reactor technology could become a cornerstone of the future nuclear energy industry, allowing companies to generate carbon-free power in a safe and efficient way. Researchers from MIT used neutron scattering at ORNL’s Spallation Neutron Source to explore the fundamental chemical and physical properties of salts at high temperatures. Their goal was to better understand how salt solutions behave in nuclear environments. The experiments will help create high-fidelity models that predict how salt solutions might perform in the intense environment of a molten salt reactor and could prove invaluable to nuclear engineers working to commercialize molten salt reactors for clean power production. Learn more about neutron science at ORNL.

Williams College in Williamstown uses ORNL-produced lead isotopes for geological dating studies.

Through a cooperative research and development agreement with Raytheon Technologies, ORNL is developing materials and processes necessary to manufacture a moderate-sized boat using the Big Area Additive Manufacturing, or BAAM, process. BAAM prints large parts as quickly as possible, using pelletized thermoplastics to reduce the typical costs associated with producing large thermoplastic parts.

The DOE Isotope Program and QSA Global Inc., a private company that supplies industrial gamma radiography, have a joint product development agreement for U.S. production of iridium-192, an isotope critical to helping industry find structural defects and damage to metal parts such as welds, castings and seams. It’s used often to assess the integrity of oil and gas pipelines and to ensure manufacturing quality in shipbuilding, vehicles, aerospace and other sectors. ORNL also provides QSA with another radioisotope used in industrial radiography, selenium-75.

Learn more about the isotope program at ORNL.

ORNL is partnering with critical metals extraction and refining company Nth Cycle in Fairfield, Ohio, to develop recycling methods for lithium-ion batteries that power electric vehicles. Researchers are improving the efficiency of Nth Cycle’s electroextraction technology, which is based on removing charged particles from spent electrodes and selectively separating metal hydroxides for reuse in new electrodes. At the Battery Manufacturing Facility at ORNL, the extracted metal hydroxide is incorporated into new cathodes, which undergo testing to demonstrate properties on par with batteries made from pristine materials.

For more information, contact [email protected].