Pennsylvania is known for its coal, steel, and agricultural output, but it also has a bustling advanced manufacturing and energy economy. A few of ORNL’s research partners in the Keystone State include ExOne, creator of 3D printing systems; Kennametal, developer of heavy-duty industrial tools and equipment; and Grid Fruit, whose machine-learning platform uses food retail data to reduce costs and emissions.

ORNL’s user facilities offer a diverse set of tools for experiments across a range of fields, including biology, materials and energy sciences, physics, engineering, and chemistry. Learn more about ORNL’s user facilities. Data reflects fiscal year 2020 except for scientific publications, which covers 2016–2020. Partner stories reflect work conducted from 2016 to present.

DOE’s National Energy Technology Laboratory in Pittsburgh continues to build on a century of energy-related research. Much of the work carried out today at NETL-Pittsburgh focuses on process systems engineering, decision science, functional materials, and environmental sciences.

Under NETL sponsorship, ORNL and the University of Kentucky investigated ways to use carbon ore to create high-value products like carbon fiber composites for the aerospace, automotive, wind energy markets, and more. The research supports environmental justice by paving the way for new manufacturing industries and good-paying jobs in American coal communities.

NETL operates three sites in Albany, Oregon; Morgantown, West Virginia; and Pittsburgh, Pennsylvania.

ORNL collaborated with Arkema Inc., a global chemicals and materials manufacturing company with a research center in King of Prussia, to investigate and characterize poly(etherketoneketone), or PEKK. PEKK was invented in the 1960s as part of the Apollo space mission, but it can now be used to replace metal components in extreme environments, such as those found in motors. Its properties were studied to better understand its use in big area additive manufacturing processes.

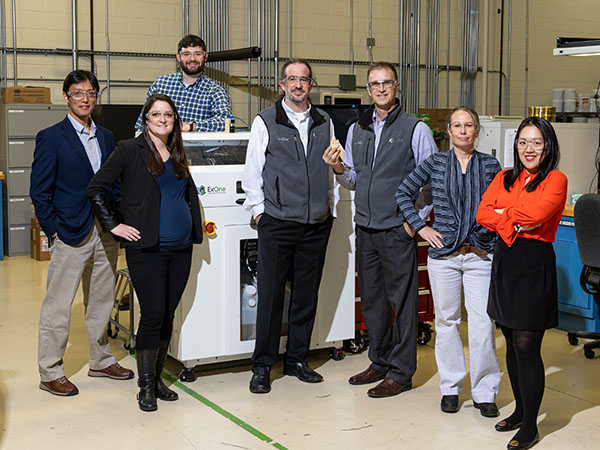

ORNL collaborated with ExOne to develop an R&D 100 Award-winning method of 3D printing that uses binder jetting technology to produce metals, such as stainless steel, bronze, or tungsten, as well as sand, ceramics, and composites. ExOne also licensed ORNL’s patented method of 3D printing components used in neutron imaging.

UGI Corporation of Pennsylvania entered an agreement with Vertimass LLC of California to use Vertimass technology to produce a sustainable aviation fuel based on advanced ethanol and biobased propane to increase American energy independence. The agreement covers the use of Vertimass’s production process based on catalytic technology first developed by, and licensed from, ORNL. The companies have a goal of producing as much as 1 billion gallons of these biobased products per year for US and European markets. The products will be distributed by UGI’s AmeriGas subsidiary in the United States and marketed by UGI International in Europe.

For more information, contact [email protected].