ORNL collaborates with the University of Utah to study fundamental physics questions. ORNL works closely with Mazak Megastir through a unique manufacturing research group and with Petersen through its critical supply role for the international ITER project.

ORNL’s user facilities offer a diverse set of tools for experiments across a range of fields, including biology, materials and energy sciences, physics, engineering, and chemistry. Learn more about ORNL’s user facilities. Data reflects fiscal year 2020 except for scientific publications, which covers 2016–2020. Partner stories reflect work conducted from 2016 to present.

Carleton DeTar of the University of Utah received hundreds of thousands of computing hours on the Summit supercomputer from 2020–2021. DeTar’s team is using Summit to study the interactions of quarks and to refine the Standard Model of Particle Physics by reducing uncertainties in its predictions. The Standard Model is scientists’ current best theory to describe the most basic building blocks of the universe.

A welding group within the national laboratory system, based at ORNL, is collaborating with Mazak MegaStir on solid-state joining methods. These methods lower costs and reduce emissions for the transportation sector. In auto manufacturing, different materials are needed in different places throughout a vehicle to support specific functions, such as making an engine less heavy or protecting passengers. Lightweight aluminum materials reduce fuel consumption, heavy steel materials offer strength, and carbon fibers offer both at a higher cost. Expertise in solid-state joining is critical to manufacturing, making it possible to join materials with unique properties.

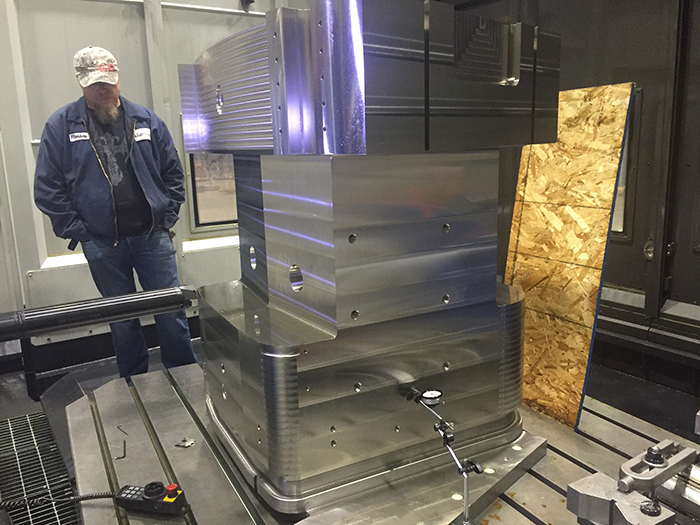

A 60-foot tall superconducting magnet fabricated in the United States will ignite the plasma for ITER, the renowned fusion project involving scientists and engineers from 35 countries. The 1,000-ton magnet requires a support system that can withstand 210 meganewtons of force—roughly six times the thrust of the first stage of a Saturn V rocket. Petersen Incorporated has fabricated and delivered more than $6 million in massive finely-machined stainless-steel magnet-support blocks for ITER. ORNL manages the US ITER project.

Learn more about fusion research at ORNL.

Listen to ORNL’s Sound of Science podcast episode “Fusion: Energy at the Extreme.”

For more information, contact [email protected].